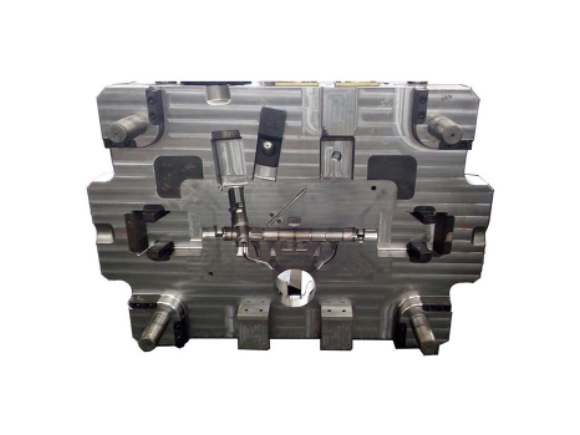

Aluminum die casting mold

Aluminum mold making

This is our aluminum die casting mold display page. We can extract 3D and 2D products from customers, and must perform mold flow simulation steps. Any potential defects were found during the aluminum die casting mold process. For example, some parts have A surface and B surface requests. Especially for nickel finishing die castings. Without any porosity margin, many parts will require a second process. Whether the bulb appears after processing. Some parts have very strict tolerances on the same axis. This time JSCAST CAE software will provide an excellent solution. In fact, all designers of aluminum die-casting mold manufacturers need advanced CAE software to help them complete their work, not just experience.

Aluminum Casting Mold Making factory can customize production equipment, but not limited to these:

Aluminum die casting telecom housing mold

Aluminum die casting auto mold

Aluminum die casting power tools mold

Aluminum die casting power tools housing mold

Aluminum die casting auto gearbox housing mold

Aluminum die casting auto water pump housing mold

Aluminum die casting light shell mold

Including Aluminum Die Casting Tools, High Pressure Die Casting Tools.

For the DFM confirmed by the customer, the raw material quality inspection step is very important, especially the core material inspection. Now the materials of H13, SKD61, 8407, 1.2344 and DH-31 are widely used in Ningbo Die Casting Mould Factory. We not only check the chemical composition and mechanical properties. Pure material standards are also very important for die casting molds. Any impurities contained in the mold core will cause cracks after thousands of injections, rough grinding, milling, and rough machining before heat treatment. After heat treatment, precision grinding and precision machining will be carried out. In our die-casting mold workshop equipped with a high-speed five-axis machining center. EDM has been widely used in the production of die-casting molds. The great advantage of this EDM machine is that it reduces the processing cost and solves the most complicated structure in the HPDC mold. The disadvantage is that corrosion problems will occur. Therefore, the selection of high-standard EDM machines is very important. After EDM, the oxidized material must be removed. Polished aluminum injection mold cavity. The roughness of the cavity is also important for the injection time of the die-casting mold. The polishing direction should be the same as the mold opening direction.

Custom Pressure Aluminum Casting for the next project

1. Types of Aluminum Casting Mold Making

There are many kinds of molds for casting aluminum, which are used to cast molten aluminum into different shapes and forms. Some molds are temporary, some are permanent and can be reused. In addition to aluminum, these same types of molds are also used in many different metals and alloys.

Sand mold

Ceramic mold

Permanent mold

Aluminum Casting Mold Making uses steel molds to produce a large number of identical castings. For aluminum, like other metals, molten metal is pressed into these types of cast aluminum molds under high pressure. This is a universal process that can produce a large number of small and medium-sized castings.

Shell mould

Plaster mold

Graphite casting mold

2.Aluminum Casting Mold Making process

Casting is the most primitive and most widely used method of forming aluminum into products. Although the technology has advanced, the principle remains the same: molten aluminum is poured into a mold to replicate the desired pattern.

The die casting process forces the molten aluminum to enter the steel mold (mold) under pressure. This manufacturing technique is usually used for mass production. This casting method can produce precision-formed aluminum parts that require minimal machining and finishing.

3. Application of Aluminum Casting Mold

Widely used in the automotive industry and households

The automotive industry is the largest market for aluminum castings. Cast products account for more than half of automotive aluminum. Since the beginning of the 20th century, cast aluminum gearbox housings and pistons have been widely used in automobiles and trucks. Small appliances, hand tools, lawn mowers and other mechanical parts are made of thousands of different unique cast aluminum shapes. The most common casting product used by consumers is cookware, which is the first aluminum product used daily.

High Pressure Aluminum Casting Molds

High Pressure Aluminum Casting Molds, sometimes called High Pressure Aluminum Casting Mould, are made of hardened steel and can withstand high temperatures and extreme pressures. There are many types of high-pressure die-casting molds. China Die Cast Dies makers can range from simple cheap inserts to complete high-pressure die-casting molds for only one part. Once the high-pressure die-casting tools are produced, Die Casting Mould Company's cost of manufacturing high-pressure die-casting parts is very low. Die Casting Factory In China, can manufacture your high pressure die casting mold or install your insert into one of our tool holders at a very competitive price. Die casting molds, aluminum parts molds. Die casting quality and dimensional accuracy

Power die casting retention is one of the outstanding features of Die Casting Producer In China. We will create an "operation sheet" that contains all the checkpoints required to ship you the high pressure die castings you want. We provide "certificates of conformity" for each batch of high pressure die castings.

We are Die Cast Mold Company/Aluminum Die Casting Mould Company, where you can get Pressure Die Casting Tooling that guarantees your maximum profit. We usually communicate with customers on the details of Pressure Die Casting Molds, and then make samples until the customer is satisfied with Pressure Die Casting Molds is satisfied.