Aluminum die casting light cover

Aluminum die casting light cover, Die Cast Mold For Lighting

Cast aluminum luminaire parts, such as lamp housings, a type of electrical enclosure, are used to protect the internal light-emitting units and other electronic components from damage caused by external harmful elements. In addition, cast aluminum lamp housings have common protection requirements with electrical housings. However, in addition to the functions mentioned above, the lamp housing should also give an aesthetic appearance, which is a bit different from the electrical housing. In a nutshell, the design of luminaire parts such as lamp housings should conform to the practicality of electrical housings and also consider the aesthetics of the luminaire.

All these require the luminaire designers to have rich experience and also need the strong support from professional lamp parts manufacturers. Goal Sure is a professional aluminum casting foundry in China, we will support you continuously from the design to manufacture of lamp parts.

Full range of aluminum castings for luminaire parts

As a professional aluminum casting factory, by utilizing our strong casting capabilities, we are able to produce a full range of light parts, including:

Street light housings/housings

Lawn light housings/housings

Garden light housings/housings

Traffic light housings/housings

Spotlight housings/housings

Wall light bracket and shell/shell

Landscape lighting housing/shell

Buried light cover/shell

Underwater light housing/shell

Light pole base

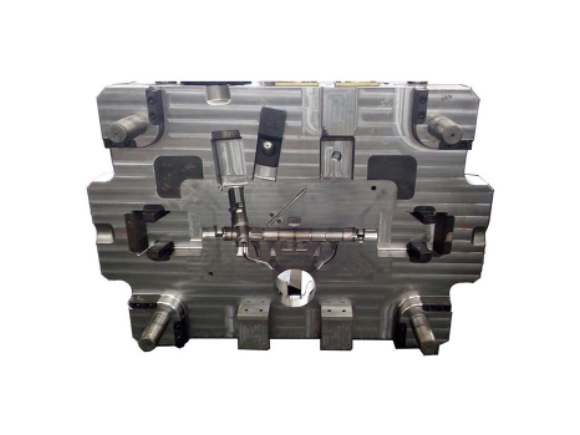

Die Casting Lighting Parts Cases

We specialize in aluminum castings for luminaire parts

As a professional manufacturer of aluminum castings, the prerequisite for providing quality cast aluminum parts is an understanding of the properties of aluminum alloys.

A key advantage of using the aluminum casting process for lamp parts is its economic characteristics - cast aluminum parts are much cheaper than parts made by other processes, such as machining or forging.

It is well known that lamps generate a lot of heat when they are in operation, especially LED lamps. From a functional point of view, the cast aluminum housing can help conduct heat in time to prevent the lamp from being damaged by high temperatures. Especially when the housing is designed with heat sink structure, the heat conduction ability is better.

Aluminum castings used for luminaire parts have many other benefits, including:

Lightweight: Cast aluminum parts are typically one-third lighter than steel parts, while still providing the strength and durability necessary for any lighting fixture.

Corrosion resistance: Cast aluminum parts have naturally superior corrosion resistance, which is critical for lighting fixtures used outdoors.

Excellent electrical conductivity: Aluminum is second only to copper in electrical conductivity.

Easy surface treatment: cast aluminum parts can be subjected to a variety of surface treatments, including painting, powder coating, electroplating, anodizing, etc.

Easy to process: cast aluminum parts have excellent processing performance, processing surface roughness up to Ra 0.8 or even better.

Easy to shape: cast aluminum parts can be processed into various shapes to meet the aesthetic interest of the lamps and lanterns.

We implement the most stringent quality control measurements

As a high quality mold manufacturer, we have advanced aluminum casting processes, highly automated processing equipment, experienced quality control personnel, precise inspection and testing equipment, and implement the most stringent quality control measures. To ensure the highest quality products for our customers, we monitor and inspect every step of the process.

Contact us for a quote on your light parts

If you have a project on hand that requires light parts, please feel free to contact us for more information on our capabilities and pricing. We are a one-stop supplier of cast aluminum parts, and you will never be disappointed when you choose us as your supplier of light parts.

Good heat treatment will make products size stable and prevent any deformation problem. 2mm-6mm thickness is most easy casting, but many corrosion resistant light fixtures thickness below 2mm. some casting bathroom light fixtures thickness even below 0.8mm. find right aluminum alloy and high pressure mold will key important. Some aluminum no suit for heat treatment.

Right ejector pin location for die casting spotlight cover should seriously. Most light cover is thin wall. Deformation problem will caused when ejector pin in not right place. Ejector pin do not located on thin wall. Surface defects like dent, extrude, will caused. Try your ejector pin located thick wall even overflow well. This is will increase your mold cost budget. Only 5%-8% increased, but your products defects rates will great reduce. Ejector pin vestige should same

Flatness with inside wall. of course ejector pin will not located A area, most case will located B and C area, but we still need careful, because inside light cover will assemble wire or electronic accessories. Any remain sharp metal is potential risk for outdoor light fixtures manufactory.

Find right powder material for corrosion resistant light shell coating, we suggest Dupont. The outdoor powder coating material from Dupont is excellent for your corrosion resistant light shell. now many china led lighting parts factory select this brand, casting aluminum light fixtures surface roughness also important for powder coating quality, this is will involve adhesive, heat chamber temperature, powder coating bracket design. All of influence factor should take into account. Now many china led lighting parts factory have their own no dust chamber powder coating line for high quality die casting parts.