Home > About Us > Our Advantages

Hannover Messe

Many china die casting mould manufactory like us attended hannover messe every year. Visitor have favorable impression with our automobile die casting mould production capability, Particularly with die casting mould for gearbox housing. People from automotive, machinery, telecom, electronics industries, interest with our super quality products.

Hannover messe organizer offer technical exchange meeting for global die cast mold maker, information exchange including, tool designs, mold flow analysis, rapid prototyping, product quality control process.

We attended technical forum during hannover messe, something is really attract us. One forum subject is robotic assistant production in industry. In fact automation production is tendency, since labor cost in china high pressure casting industry increasing a lot during ten years, now all of our die casting machines already equipped with automatic spraying, automatic feeding, automatic fetching, automatic deburr by four axle robotic polishing machines.

We also visit many German die casting mold company and local die casting producer, many of them are business competitive.

Visit Our Customer During Shanghai International Marine Industry Exhibition

Mr Ma visit our customer during shanghai international marine industry exhibition, discuss our die casting components quality and our service. They appreciated our customized die casting service. ABB provide much electrical apparatus for their marine customer. corrosion and leakage testing request from them very strict. For the new project we will need adjustment few times to solved assemble problem.

This is very common phenomenon in new model machine. Every time we fellow the 3D and 2D drawing. But customer always change drawing to fit assembling or to meet function. Anyway customer always right. Experiences die cast mold company knew how to do it. High quality Heat treatment and industry PVD coating for mold core will increasing high pressure die casting tools injection times. Please do not PVD coating for your die casting molds before customer make finally decision.

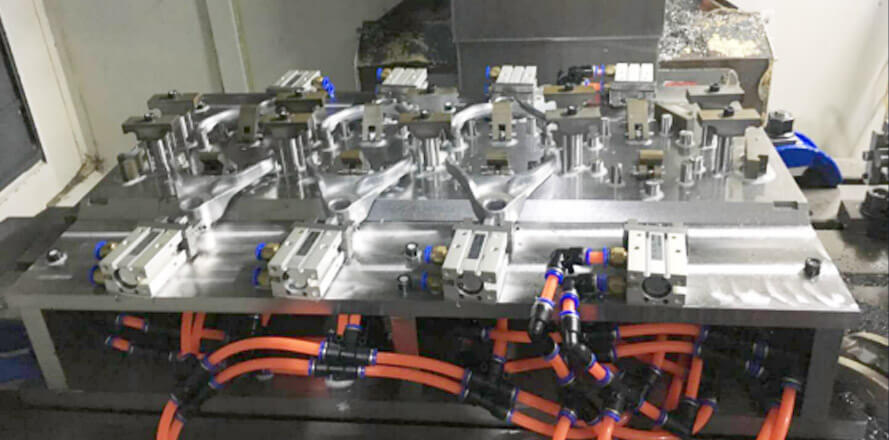

Customer visit for Aluminum die cast Shift fork

Raw material quality is very important for PDC shift fork. how about your normal material hardness? The normal die casting aluminum alloy hardness only control 78HB-85HB. This is not enough. So looking the quality raw material is critical for your project. The material of ADC14 and R14 is popularly for casting aluminum shift fork. But whatever ADC14 or R14, normal hardness only around 80HB before treatment. Ask your local material supplier increasing hardness around 95HB-100HB. But how about their treatment technical and facility? Just as you know contradictory between hardness and fragility.

We will calculate parts weight and analysis project area for fit die casting machines, 280 cold chamber die casting machines is powerful enough for ordinally parts in same project area and weight. We are one gear shift fork manufactory in china. Experiences told us this is high risk for die casting aluminum shift fork when we produce by low power machine. We quite understand some pressure die casting company thinking, they try to reducing energy emission, But for high pressure casting shift fork is totally wrong. Ask your local aluminum die casting molds company produce two cavity mold, casting by 400T cold chamber die casting machine. Eliminate air and impurity is necessary step during casting, so it will need two melting furnace. Casting temperature control around 680 degree.